In many university research labs, fluid handling is a routine task—but when you start working with viscous fluids, non-Newtonian materials, or experiments involving high pressure and back pressure, ‘routine’ quickly turns into ‘challenging.’

Whether investigating new materials, studying reaction kinetics under pressure, or running pilot-scale experiments, precise control over thick or pressurised fluids can be difficult. Traditional syringe pumps often fall short—not because they’re poorly made, but because they simply weren’t designed for the demands of these specific research environments.

This is where a high-pressure syringe pump can make a real difference.

Performance Under Pressure: Why Standard Pumps Fall Short

Research involving viscous or non-Newtonian fluids brings a unique set of mechanical challenges. As viscosity increases, so does the force required to push the fluid through tubing, microchannels, or reaction vessels. Add high system back pressure in flow chemistry, hydrogenation, or microfluidic filtration, and standard syringe pumps are pushed far beyond their design limits.

Here’s what researchers typically face in these situations.

Inconsistent Flow Rates

High-viscosity fluids often cause uneven or pulsed flow with standard pumps, especially at lower speeds. This can throw off flow-dependent reactions or experiments that require continuous dosing.

Mechanical Wear and Tear

The strain from pushing dense fluids under pressure can lead to premature wear or even failure in pumps not built for it. Plastics may flex, motors may stall, and flow control becomes unreliable.

Temperature Sensitivity

Many viscous fluids are also temperature sensitive. Their flow characteristics can shift with even small temperature changes, making it hard to maintain consistent dosing without additional control systems.

Precision Pressure Control

Holding and adjusting internal pressure is crucial for many pressure-driven applications, like fracking simulation or catalyst infusion. Few general-purpose syringe pumps offer pressure monitoring or the precision required for this level of control.

To address these challenges, researchers need a pump that doesn’t just deliver fluid—it needs to do so with power, precision, and reliability under demanding conditions.

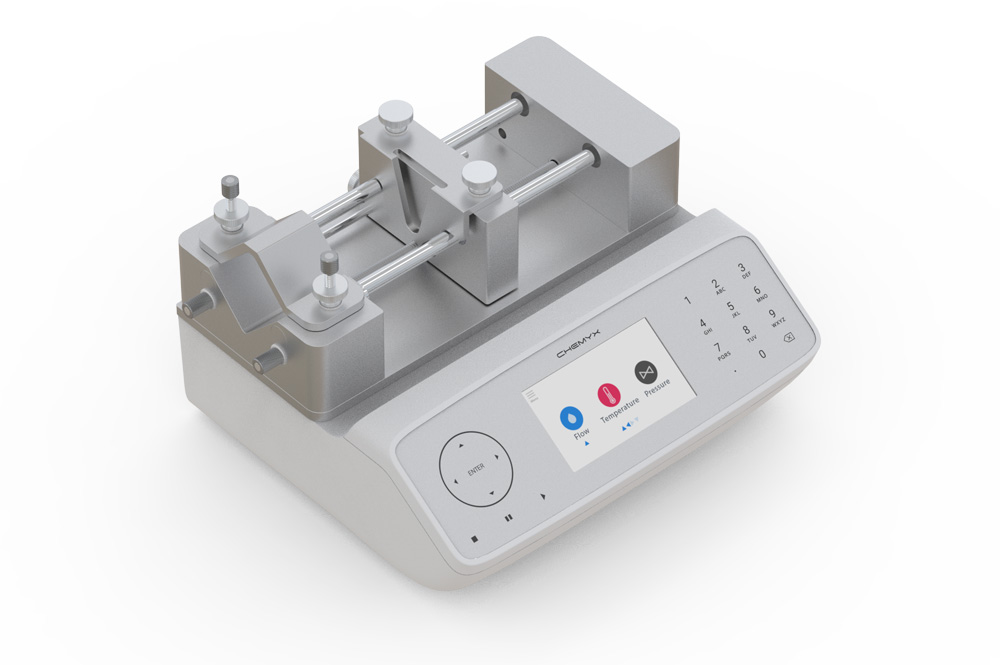

Designed for Demanding Applications: The Fusion 6000-X High-Pressure Syringe Pump

If any problems above sound familiar, the Fusion 6000-X high-pressure syringe pump was built with your work in mind. It’s engineered specifically to handle high-viscosity liquids, high-pressure setups, and experiments where control and repeatability are critical.

Built to Push Hard

This pump’s core is a micro stepper motor capable of producing up to 700 lbs (318 kg) of linear force. That means you can push viscous or pressurised fluids without worrying about stalling, stuttering, or inconsistent flow. Whether you’re working with gels, emulsions, slurries, or dense polymers, this pump delivers confidently.

Precision Without Compromise

Despite the force, precision isn’t sacrificed. The motor allows for smooth, accurate, and highly reproducible microflow dosing, even under demanding conditions. It’s ideal for a range of flow rate applications (0001 µL/min to 408 ml/min) that require high resolution and stability.

Materials That Work as Hard as You Do

The pump’s machined metal frame and hardened-steel guide mechanisms can handle years of high-load operation. These components resist flexing under pressure, essential for maintaining alignment and accuracy over time. The chemical-resistant, all-glass screen and rugged exterior make it a reliable choice even in busy, mixed-use university lab environments.

Adaptable for Temperature and Pressure Control

To tackle viscosity shifts caused by temperature fluctuations, the system supports heated syringe sleeves, helping you maintain consistent fluid properties throughout your experiment. Pair this with an optional vacuum transducer pressure sensor, and you can actively monitor and maintain constant pressure during dosing.

- Hydrogenation experiments

- Fracturing research (fracking R&D)

- Flow chemistry

- Controlled infusion into pressurised chambers or microreactors

Smart, User-Friendly Software

The pump has intuitive software that lets you program variable-rate infusion profiles via a touchscreen or remote connection using USB, RS232, or TTL interfaces. The system is also compatible with LabVIEW ,MATLAB,LABWINDOWS and PYTHON making integrating the pump into your existing workflows or custom automation setups easy.

Who is the Fusion 6000-X High-Pressure Syringe Pump for?

This pump isn’t just for high-end industrial research—it’s designed with academic labs in mind. That means:

Affordable pricing to fit within research grants and university budgets.

Long-term durability to serve multiple research projects.

Two-year warranty for peace of mind.

Whether in chemical engineering, materials science, bioengineering, or environmental research, if your experiments involve high viscosity, pressure, or precision flow, this pump is ready to meet your lab’s needs.

Final Thoughts: The Right Tool for the Right Job

University research is full of complex problems, and that’s normal. But progress slows when your equipment can’t keep up with your ideas. The high-pressure syringe pump helps bridge that gap, giving you the power and precision to keep exploring without compromise.

So, if you’ve been wrestling with viscous fluids, inconsistent dosing, or pressure-sensitive experiments, and are looking for a reliable way to enhance your lab’s precision, reproducibility, and efficiency, we’re here to help.

For over 35 years, KR Analytical has worked alongside researchers across all disciplines to find the right technical solutions for their studies and laboratory setups. We understand the challenges you face—and how important it is to have equipment you can rely on daily.

Get Your Custom Quote – Accurate pricing based on your specific research setup.